• Air Filtration: Preventing particle entry through air filtration systems or sealing air gaps.

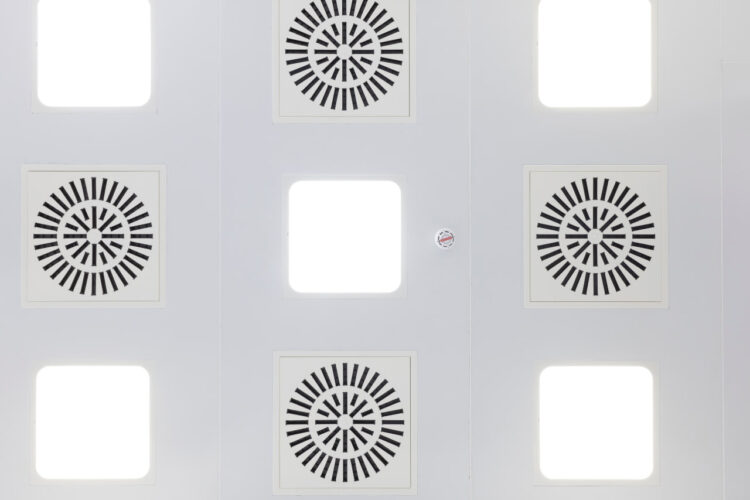

• Air Purging and Filtration: Continuous purification of room air throughout the production process.

• Differing Cleanliness Levels: Incorporating parallel stages and adjacent rooms with varying cleanliness levels, such as gowning or garbing rooms, anterooms, and buffer rooms for preparation and storage.

• Isolated Clean Spaces: Creating isolated environments with controlled air pressure, such as laminar flow hoods for sterile compounding or handling hazardous chemicals.

To maintain cleanroom integrity, the area leading into a cleanroom should be as clean as the room itself. Personal items like keys, watches, rings, matches, lighters, and cigarettes should be securely stored in personal lockers outside the gowning room.

Hand Washing Best Practices for Cleanrooms

While wearing gloves is standard in cleanrooms, it’s essential to prioritize hand hygiene. Individuals wearing gloves are less likely to wash their hands before donning gloves, increasing the vulnerability of cleanrooms to bacteria and microbe transfer. Effective hand washing should last at least 15 seconds with soap and water, and the use of paper towels is prohibited. Instead, HEPA-equipped hand dryers should be used.

Garments and Fabrics

Cleanroom garments must meet specific criteria:

Low particulate shedding

Breathable for comfort

Efficient particle retention within the garment

Durable for repeated cleaning and sterilization

Static control, if required

Opacity compliance

Cost-effectiveness

Cleanroom fabrics should also maintain a desirable look and feel.

Ref:

Sandle, T., 2014. People in cleanrooms: understanding and monitoring the personnel factor. Journal of GXP Compliance, 18(4), pp.1-5.

Holbrook, D., 2009. Controlling contamination: the origins of cleanroom technology. History and Technology, 25(3), pp.173-191.

https://www.cleanroom-industries.com/index.php/resources/common-cleanroom-contaminants/453

Our Projects

Our Projects  Docs

Docs  Support

Support