Technologies that Safeguard Cleanroom Integrity

Introduction

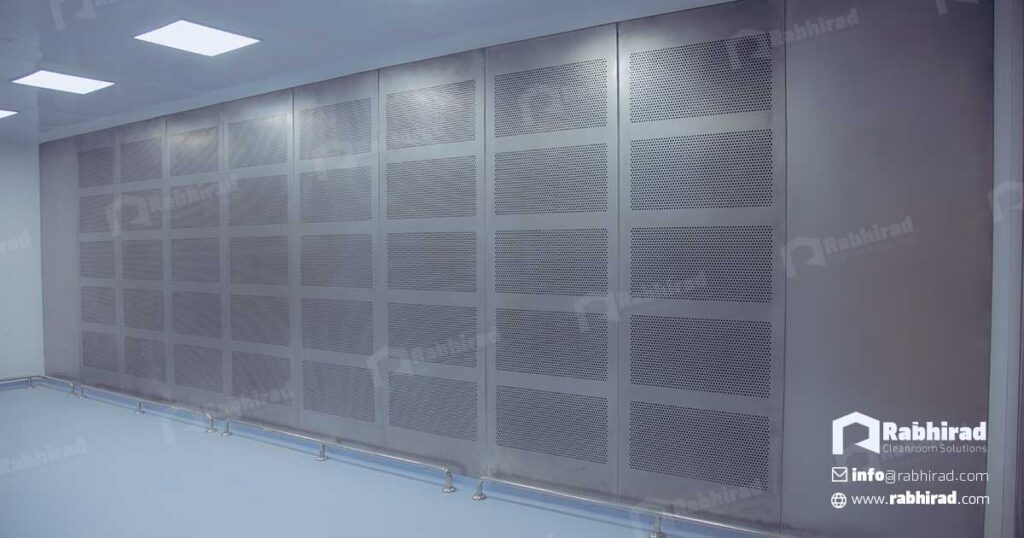

In industries where precision and cleanliness are paramount, such as pharmaceuticals, biomedicine, and semiconductor manufacturing, the integrity of the cleanroom environment is non-negotiable. Cleanrooms are meticulously designed spaces that minimize contamination and maintain controlled conditions for sensitive processes. To achieve this, sophisticated monitoring and control systems are employed, which play a critical role in measuring and regulating the cleanroom environment and its equipment.

The Role of Monitoring and Control Systems

Monitoring and control systems in cleanrooms are integral to ensuring that environmental parameters such as temperature, humidity, air pressure, and particulate levels remain within specified limits. These systems encompass a variety of technologies, including sensors, cameras, and data acquisition systems, all of which work in concert to provide real-time data and facilitate immediate adjustments as necessary. These systems help to ensure that the cleanroom environment remains at the desired levels for the process and keep contaminants out of the cleanroom. They monitor the cleanliness of the air and surfaces, and may also monitor equipment. These monitoring and control systems are essential to maintain a consistent and stable environment and to prevent potential contamination.

RabHirad is at the forefront of providing specialized services and consultation in the field of monitoring and control systems for cleanrooms. With a focus on implementing cutting-edge technologies and systems tailored to the unique needs of various industries, their services also include consulting and staff training, which ensures that customers can trust the company.

Components of Monitoring and Control Systems

1. Sensors: At the heart of any monitoring system are sensors that measure critical environmental parameters. These sensors can detect temperature fluctuations, humidity levels, air pressure variations, and the presence of airborne particles. For example, particulate matter sensors can identify contaminants in the air.

2. Cameras: Visual monitoring is also crucial in cleanroom environments. Surveillance cameras can be employed to oversee activities within the cleanroom, ensuring compliance with protocols and identifying any potential breaches in cleanliness standards.

3. Data Acquisition Systems: These systems collect data from various sensors and cameras, providing a comprehensive overview of the cleanroom environment. The data is often transmitted to a central control system for analysis, allowing operators to monitor conditions in real time.

4. Control Systems: Once data is collected and analyzed, control systems can take action to adjust environmental conditions as needed. For example, if a sensor detects a rise in temperature beyond acceptable limits, the control system can activate cooling mechanisms to restore the desired conditions.

5. Alert Systems: In the event of a deviation from established parameters, alert systems notify operators of potential issues. This allows for rapid response to prevent contamination or equipment malfunction.

Real-Time Monitoring and Rapid Response

The primary objective of monitoring and control systems is to maintain a stable and sterile environment, which is crucial for various applications, particularly in the fields

Technologies that Safeguard Cleanroom Integrity

Introduction

In industries where precision and cleanliness are paramount, such as pharmaceuticals, biomedicine, and semiconductor manufacturing, the integrity of the cleanroom environment is non-negotiable. Cleanrooms are meticulously designed spaces that minimize contamination and maintain controlled conditions for sensitive processes. To achieve this, sophisticated monitoring and control systems are employed, which play a critical role in measuring and regulating the cleanroom environment and its equipment.

The Role of Monitoring and Control Systems

Monitoring and control systems in cleanrooms are integral to ensuring that environmental parameters such as temperature, humidity, air pressure, and particulate levels remain within specified limits. These systems encompass a variety of technologies, including sensors, cameras, and data acquisition systems, all of which work in concert to provide real-time data and facilitate immediate adjustments as necessary. These systems help to ensure that the cleanroom environment remains at the desired levels for the process and keep contaminants out of the cleanroom. They monitor the cleanliness of the air and surfaces, and may also monitor equipment. These monitoring and control systems are essential to maintain a consistent and stable environment and to prevent potential contamination.

RabHirad is at the forefront of providing specialized services and consultation in the field of monitoring and control systems for cleanrooms. With a focus on implementing cutting-edge technologies and systems tailored to the unique needs of various industries, their services also include consulting and staff training, which ensures that customers can trust the company.

Components of Monitoring and Control Systems

1. Sensors: At the heart of any monitoring system are sensors that measure critical environmental parameters. These sensors can detect temperature fluctuations, humidity levels, air pressure variations, and the presence of airborne particles. For example, particulate matter sensors can identify contaminants in the air.

2. Cameras: Visual monitoring is also crucial in cleanroom environments. Surveillance cameras can be employed to oversee activities within the cleanroom, ensuring compliance with protocols and identifying any potential breaches in cleanliness standards.

3. Data Acquisition Systems: These systems collect data from various sensors and cameras, providing a comprehensive overview of the cleanroom environment. The data is often transmitted to a central control system for analysis, allowing operators to monitor conditions in real time.

4. Control Systems: Once data is collected and analyzed, control systems can take action to adjust environmental conditions as needed. For example, if a sensor detects a rise in temperature beyond acceptable limits, the control system can activate cooling mechanisms to restore the desired conditions.

5. Alert Systems: In the event of a deviation from established parameters, alert systems notify operators of potential issues. This allows for rapid response to prevent contamination or equipment malfunction.

Real-Time Monitoring and Rapid Response

The primary objective of monitoring and control systems is to maintain a stable and sterile environment, which is crucial for various applications, particularly in the fields of cellular therapies and pharmaceutical manufacturing. One of the most significant advantages of modern monitoring and control systems is their ability to provide real-time data. For instance, if a sensor detects an increase in particulate levels, the system can immediately alert operators, who can then initiate decontamination protocols. This proactive approach not only mitigates risks but also enhances overall operational efficiency.

A pertinent example of advanced monitoring systems in action can be found in the article titled “Online air velocity control, temperature and humidity monitoring system for cleanroom using Raspberry Pi“, published in 2019.

This article explores the benefits of using new technologies for monitoring and controlling the environment and processes in cleanrooms, particularly in industries like biomedicine and pharmaceutical manufacturing. The article highlights the importance of advanced monitoring systems for providing real-time data on the environment and processes, thereby increasing the efficiency, accuracy, and safety of cleanrooms. It also discusses the developments in monitoring and control systems, as well as the challenges and opportunities associated with them. In this article, the authors use advanced monitoring systems in cleanrooms such as sensor and computer systems, air-conditioning systems, and automated control systems. These systems help to monitor and control various factors in the cleanroom environment, such as temperature, humidity, pressure, and dust levels. These systems can provide real-time data to the operator and help to make adjustments to the environment as needed. The operators can use this data to adjust the environment, equipment, and processes to maintain a consistent and stable environment for cellular therapies and manufacturing processes.

The integration of technologies such as the Raspberry Pi into cleanroom monitoring systems represents a significant advancement. These systems allow for the automation of environmental controls, enabling operators to make data-driven decisions quickly.

Challenges and Opportunities

While the development of advanced monitoring and control systems presents numerous benefits, it also comes with challenges. The initial costs of implementing such systems can be considerable, and the complexity of the technology may require specialized training for operators. However, the long-term advantages; such as reduced contamination rates, improved efficiency, and enhanced product quality; far outweigh these initial hurdles.

Moreover, as technology continues to evolve, opportunities for further innovation abound. The increasing use of artificial intelligence and machine learning algorithms in monitoring systems promises to enhance predictive capabilities, allowing for even more proactive management of cleanroom environments.

In the ever-evolving landscape of cleanroom technology, embracing these monitoring and control systems is not merely an option; it is a necessity for ensuring the highest standards of quality and safety in critical manufacturing processes.

Journal Reference:

Sunardi A, Agus D, Aditya H, Susila W. Online air velocity control, temperature and humidity monitoring system for clean room using Raspberry Pi. InIOP Conference Series: Materials Science and Engineering 2019 Jul 1 (Vol. 550, No. 1, p. 012011). IOP Publishing.