Rabhirad cleanroom validation aligns with ISO 14644-3 standards, and various performance tests are conducted:

Airborne Particles Count: The Particle Count Method determines actual particle counts per unit volume of air through microscopic analysis. This method is meticulous but vital to maintain low dust concentrations.

Airflow Test: This measures supply airflow in unidirectional and non-unidirectional cleanrooms. It ensures velocity measurement and uniformity, aiding in calculating airflow volume and air change rates.

Air Pressure Difference Test: Validates the cleanroom’s air movement system’s ability to maintain specified pressure differentials. This test follows successful criteria from other airflow tests.

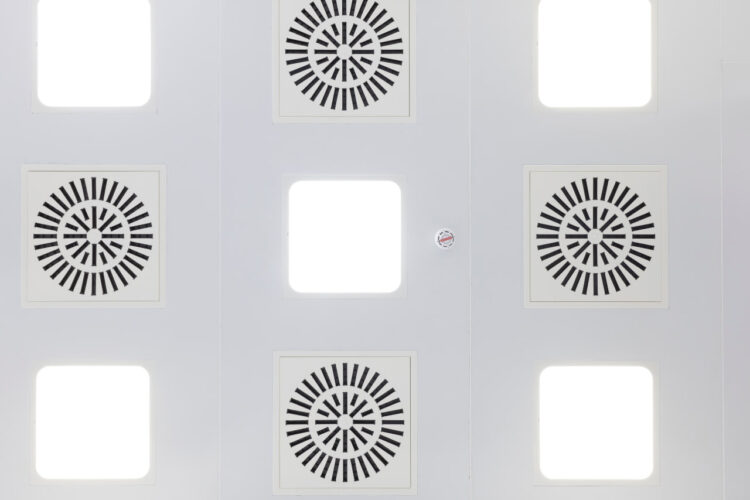

Installed Filter System Leakage Test: Confirms the proper installation of high-efficiency air filters and checks for defects, leaks, and bypass leakage.

Airflow Direction Test and Visualization: Demonstrates that airflow direction and uniformity conform to design specifications, assessing airflow patterns.

Temperature and Humidity Tests: Verify that air temperature and moisture levels stay within control limits as specified by the customer.

Electrostatic and Ion Generator Tests: Evaluate electrostatic voltage levels, static-dissipative properties, and ionizer performance for electrostatic control.

Particle Deposition Test: Checks the quantity and size of particles deposited from the air onto surfaces over a designated time.

Recovery Test: Determines the cleanroom’s ability to return to a specified cleanliness level within a finite time after exposure to airborne particulate challenges.

Containment Leak Test: Identifies intrusion of unfiltered air from outside the cleanroom through joints, seams, doorways, and pressurized ceilings.

Segregation Test: Assesses airflow’s separation effectiveness, challenging less classified areas with particles and measuring particle concentration in protected areas.

Rabhirad is working with the best validation companies in Iran that can validate the cleanroom based on Iran FDA GMP. These companies are cooperating with the Iran FDA and Approve your factory GMP validation.

Guidelines for conducting these tests are detailed in ISO 14644-3 (2019) sections B.1 to B.11.

This comprehensive overview of cleanroom standards and testing procedures ensures controlled environments meet stringent quality requirements.

Our Projects

Our Projects  Docs

Docs  Support

Support